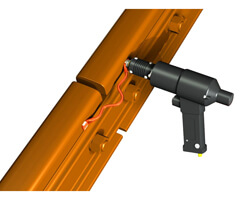

SafeBond® is a Patented Portable Indirect Arc Bonding Method with unique features:

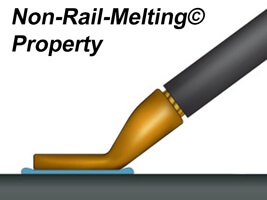

The bonding system that can attach cables anywhere on the rail — even on the base of the hardest premium rails, if necessary. Non-Rail-Melting© Feature: SafeBond® does not melt the steel of the rail, unlike thermite welding.

The patented SafeBond® system, developed by Safetrack, has already proven its superiority for more than a decade, being the only cable connection method in the world capable of being used on the hardest premium rails in the railway industry.

As the use of harder rail steels continues to increase, the SafeBond® silver soldering method has been developed to meet the demand for a safe and efficient way to create electrical connections to the rails — forming a truly Safe Bond.

Since hardening effects occur when the rail temperature exceeds 720°C (1328°F), the method is based on a special silver alloy with a lower melting temperature. This alloy is placed beneath the copper cable lug and melted using an electronically controlled amount of energy supplied by a 36 V DC battery unit.

SafeBond® can also be used with great advantage on pipelines — where the highest metallurgical requirements apply — for cathodic protection installations.

Download SafeBond® Brochure

The new lightweight PinBrazing/SafeBond unit Econect™ is preset to operate both systems (different guns required).

Used for over a decade by the Union Pacific RailRoad.

For sales to the US and Canada please contact our distributor in this area, Stanley Hydraulic Tools a member of the Stanley Black and Decker Group.

SafeBond® Patented unique features:

- Low temperature. Even lower than the PinBrazing method and

MUCH lower temperature compared to thermite welding.

- Non-Pipe melting© Feature. SafeBond® does not melt down

the steel in the Pipeline as for example thermite welding does.

- No metallurgical impact on parent material. Safe for any steel structure.

- Fast Method. A SafeBond® brazing takes only a few seconds.

- Battery powered.

- Lightweight unit. Less than 10 kg. (Econect©)

- Safe for the operator.

SafeBond® is a regisered trademark by Safetrack®, Sweden.

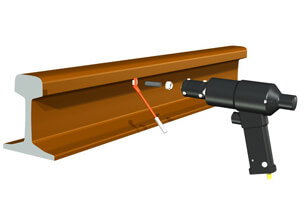

SafeBond® Principle

The process of applying a SafeBond® is remarkably easy. The whole process takes just 1-2 minutes.

1. Grind the surface. The grinding machines are either powered with the SafeBond® unit or cordless.

2. Apply a small amount of the special SafeBond® Flux on the rail and on the top of the cable lug.

3. Insert the braze electrode and ferrule in the gun.

4. Hold the gun against the cable lug and the rail.

5. Pull the trigger. The process is completed automatically after a few seconds.

Finished!