Drilled electrical rail bond fittings for rail. Patented.

SafePlug® is a Swedish-developed system for drilled electrical rail connections, designed to provide safe and long-lasting electrical bonding in demanding railway environments.

The system is used for signaling, power supply, and protective earthing on both railway and tramway rails.

Installation

To install SafePlug®, a rail drilling machine and a special rail drill are used to make the hole in the rail.

The tinned copper bushing is then expanded into the drilled hole using a torque wrench and a special installation tool.

Finally, the cable lug is fastened with the included screw assembly.

The entire process is quick, simple, and requires no heavy hydraulic tools.

SafePlug® is approved by Trafikverket (the Swedish Transport Administration) for drilled cable connections and is developed to withstand even the most extreme Scandinavian weather conditions.

SafePlug® Single - Drilled rail connection for a single cable

SafePlug® Single is designed for the secure and durable connection of a single cable to the rail.

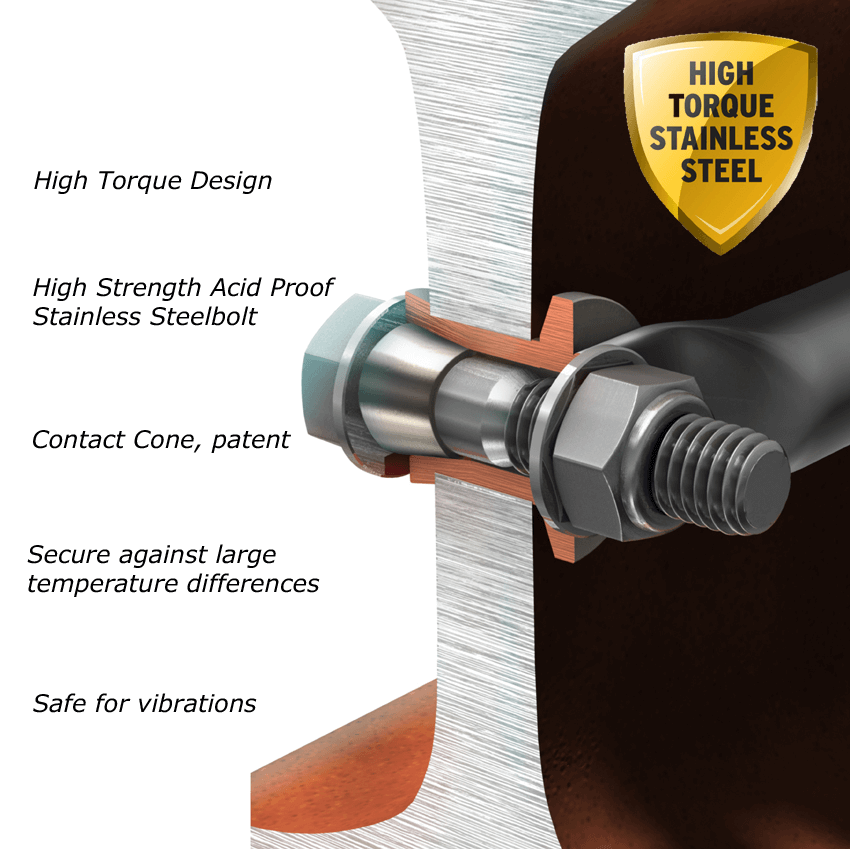

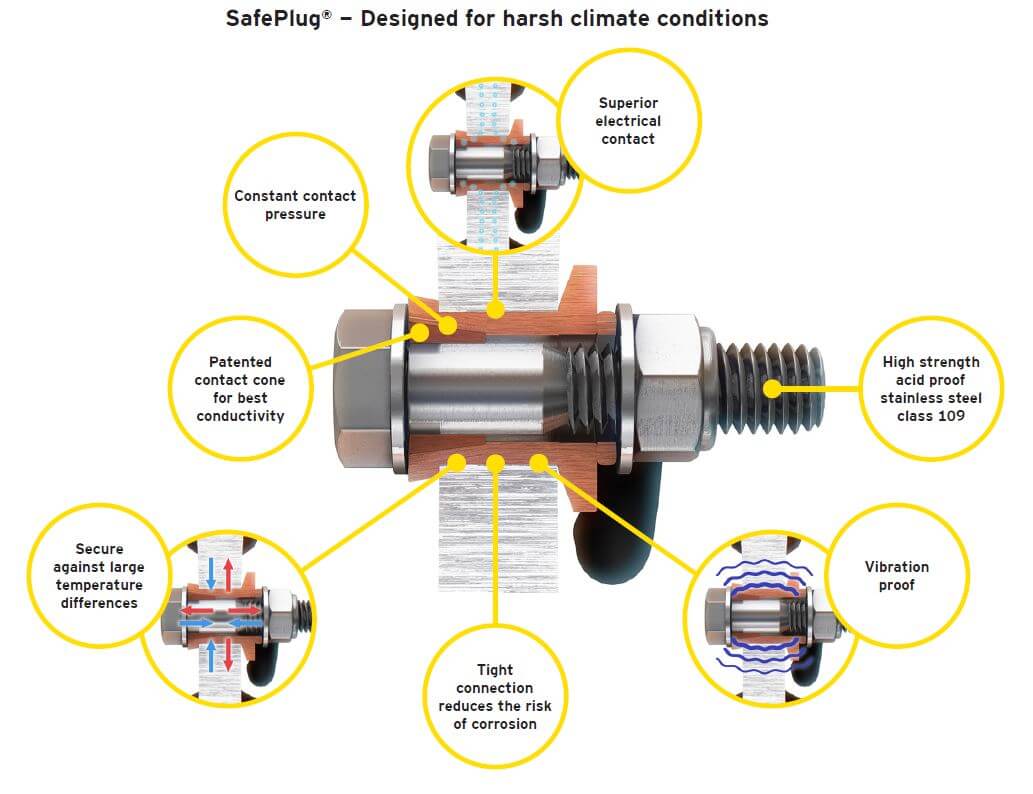

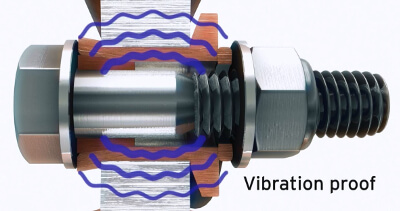

Its unique construction, featuring a tinned copper bushing and a patented copper cone, maintains constant contact pressure between the rail and the connector – ensuring low transition resistance and excellent conductivity.

The system’s high-strength stainless steel bolt keeps the connection stable under vibration and temperature variations.

Thanks to its robust design, SafePlug® Single can be installed in any weather and is suitable for signaling, power, and earthing applications.

Independently tested by NEFI (ABB):

– 35,000 A (M12)

– 25,000 A (M10)

Benefits:

- Low contact resistance

- Resistant to vibration, weather, and corrosion

- No hydraulic tools required

- Easy installation and cable removal

- Dual contact surfaces for reliable performance

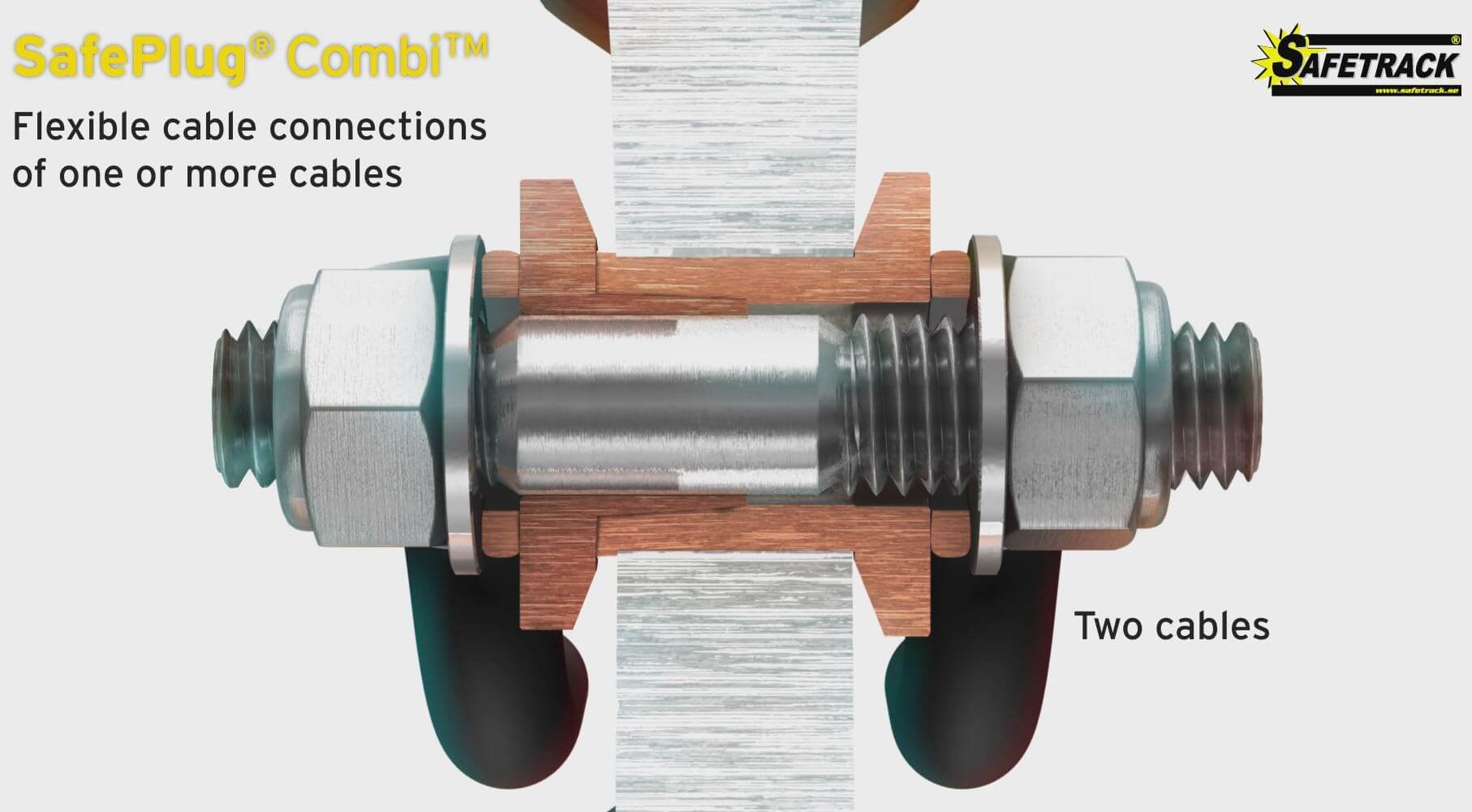

SafePlug® Combi - Flexible rail connection for one or multiple cables

SafePlug® Combi provides a flexible solution for drilled rail connections where one or more cables need to be attached at the same point.

The system allows individual cable replacement without removing the entire plug – ideal for maintenance and upgrades in the field.

Its tinned copper bushing and patented copper cone ensure consistent contact pressure between the rail and connector, resulting in low resistance, excellent conductivity, and long-term reliability – even under vibration, corrosion, and extreme temperature changes.

SafePlug® Combi is approved by Trafikverket and widely used for signaling, return current, and earthing applications in both railway and tramway infrastructure.

Installation is quick and safe using standard tools – with no need for hydraulic equipment.

Benefits:

- Flexible – connects one or multiple cables

- Individually replaceable cable connections

- Vibration and corrosion resistant

- Long service life

- No hydraulics required

- Designed for extreme temperature variations

What makes SafePlug® unique?

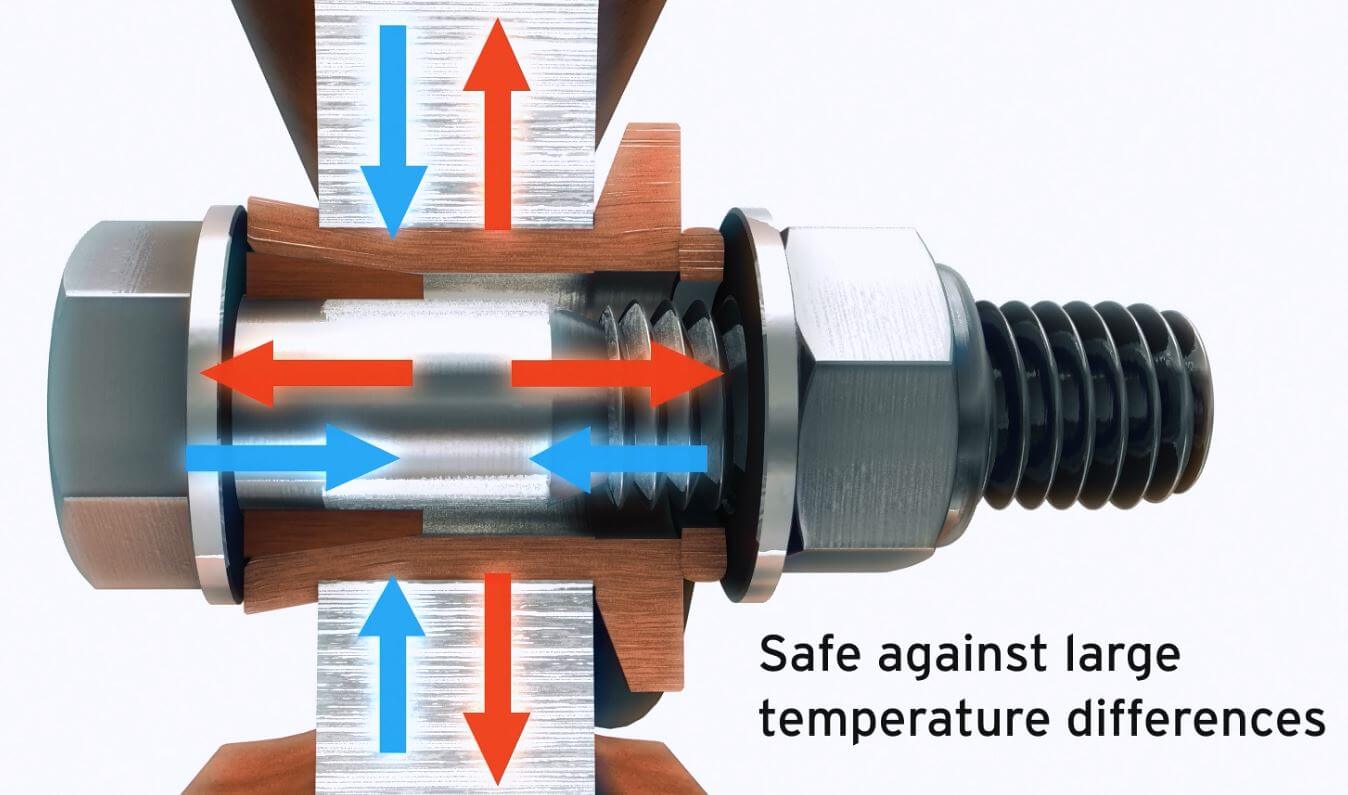

Traditional drilled rail plugs often fail to account for the large temperature fluctuations typical of the Nordic climate.

As rails expand and contract between winter and summer – and even between day and night – the contact pressure between the rail and the plug changes, leading to corrosion, loose connections, or contact faults.

SafePlug® eliminates these issues through its patented design, combining a tinned copper bushing and cone with a high-strength stainless steel bolt.

This creates constant contact pressure and low electrical resistance throughout the product’s lifetime – even under vibration and extreme weather conditions.

With no need for hydraulic tools, installation is fast, safe, and cost-effective.

SafePlug® has become a trusted standard within the railway industry for reliable electrical bonding in rail systems.

Downloads and Videos

Brochure SafePlug® BD

Brochure SafePlug® Combi

Brochure SafePlug® English

Brochure SafePlug® French

Brochure SafePlug® German